Paragon’s precision manufacturing capabilities are core in our ability to provide space qualified or military grade products to our customers. Whether it’s fabricating a quick turn prototype for a spacecraft thermal control subsystem or completing final build of a critical life sustaining environmental control sub-system, the manufacturing department’s role is central to the successful delivery of high-quality products to a demanding marketplace.

Manufacturing & Assembly

Controlled Assembly

10,000 sq. feet easy-access high bay Class 8 Clean Room

2,500 sq. feet of Machine and Fabrication Space

Class 0 Electronic Assembly Work Center (ESD)

Inspection

We use the latest in CMM technology to inspect both in-process and finished machine parts and assemblies.

Gantry-CMM, Fixed Granite Surface Plate with measurement range of 59’x118’x40’

Portable CMM Arm with 98” reach mounted on Fixed Granite Surface Plate

Portable CMM Arm with 79” reach mounted on Portable Granite Surface

Logistics & Control

Manufacturing logistics including barcoded inventory control & material management, purchase order and shipping work center assignments, WIP tracking using E2 Shop Control Software.

Our manufacturing department supports all of Paragon’s programs and provides low volume, quick turn mechanical solutions to a growing list of aerospace organizations. This work includes the creation of component prototypes, the delivery of production hardware, and the development of low volume obsolescence solutions to our civilian and Government customer base.

Precision Manufacturing

3 Axis CNC Milling

Maximum envelope

48” x 110” x 12”

CNC Turning

Maximum

diameter 8.00”

3 Printer

Evaluate form and

fit of components

4 Axis CNC Milling

Maximum envelope

12” x 18” x 18”

2 Axis CNC Waterjet

Maximum envelope

12” x 12” x 1”

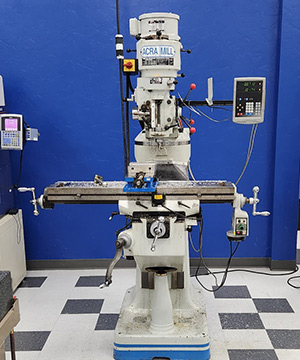

Traditional Machining

Manual Lathe

Manual Mill

Surface Grinder

Precision Tube Bending and Orbital Welding

Precision Thin Wall Tube Bending

- AS33611

- Outside Diameters from .125”-2.250”

- Stainless Steel

- Titanium

- Aluminum

- Copper

- Solid Rod

- Inconel

- Monel

Standard Tolerances

- +/- .060” from port to port standard/li>

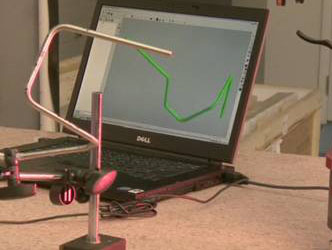

- Romer arm comparison to CAD file on each part

Linear and Orbital Tube Welding

- AWS D17.1

- NAVSEA S9074-AQ-GIB-10

- Outside Diameters from .250”-1.00”

- Wall Thickness .028”-.065”

- Each weld configuration is independently certified