Image Courtesy of Northrop Grumman

Life Support

Image Courtesy of Northrop Grumman

Modularized Air Systems

Environmental Controls & Life Support Systems

(ECLSS)

Paragon designs & manufactures fully modular life support systems (open & closed loop) which meet or exceed NASA human mission safety standards and can be used for commercial applications. Part of Paragon’s design philosophy is system commonality. Paragon’s “Common ECLSS” approach allows for our systems to work on multiple vehicles and mission types, thereby decreasing non-recurring design cost and schedule. Each subsystem in ECLSS interacts with the other systems and the crew, making it central to the success of human space exploration and human presence in space.

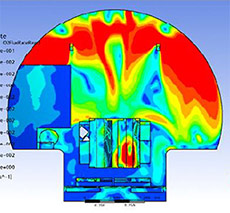

Atmospheric Ventilation and Supply

Paragon uses analytical tools and human space flight experience to design, build & deliver Atmospheric Ventilation systems that are customized for the vehicle internal volume and layout. The system is designed to ensure sufficient mixing of gases, avoid stagnation, and accommodate temperature, humidity, CO2 and trace contaminants requirements. Paragon is currently designing and assembling the Atmospheric Ventilation System (AVS) for the NASA Gateway HALO Program.

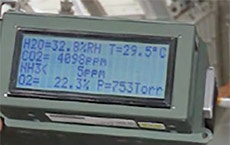

Atmospheric Monitoring Systems

Detecting rapidly harmful or toxic gases is critical to the health and safety of the crew of a spacecraft or other enclosed spaces. The Atmospheric Monitoring System (AMS) developed by Paragon detects and measures air constituents in the cabin atmosphere. The system also incorporates a state-of-the-art smoke detector designed for microgravity environments. The AMS can be fully integrated with other ECLSS functions or modularized to function independently or replace an existing technology.

Atmosphere Revitalization Systems

Paragon’s ARS forms the core of ECLSS by performing key life support functions:

- Atmospheric Temperature and Humidity Control

- Carbon Dioxide Removal

- Oxygen Production

- Air Filtering and Trace Contaminant Control and Removal

- Cabin Air Circulation and Ventilation

- Air Constituent Monitoring

- Smoke Detection and Post Fire Recovery

Humidity Control Subassembly

Paragon’s Humidity Control Subassembly (HCS), which incorporates our patented Ionomer-membrane Water Processing (IWP) technology and provides cabin atmospheric humidity control, using no moving parts, aboard Boeing’s Crew Space Transportation (CST)-100 Starliner. The modularity and simplicity of the system makes it ideal for crewed space missions as well as commercial use in non-space applications such as mine shelters and submarines.

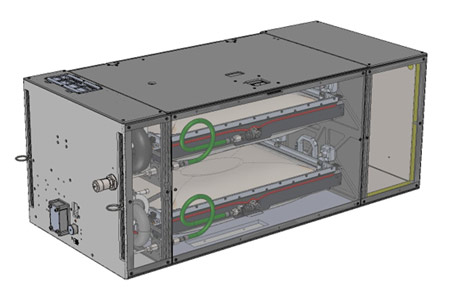

Water Recovery Systems

Paragon designed and patented its Ionomer-membrane Water Processor (IWP) technology to improve and simplify the water recovery process for space applications. IWP utilizes the forced convection of dry spacecraft cabin air coupled with membrane distillation to purify and recover available water. The IWP-based Brine Processor Assembly (BPA) was launched to the ISS in February 2021 and increases water loop closure from 93% to >98%, an essential step in developing ECLSS for deep space missions, as well as providing a key cost savings technology for government and commercial long-duration crewed missions. Paragon is currently developing additional innovative water processing technologies for commercial space station programs.

Brine Processer Assembly (BPA)

Detecting rapidly harmful or toxic gases is critical to the health and safety of the crew of a spacecraft or other enclosed spaces. The Atmospheric Monitoring System (AMS) developed by Paragon detects and measures air constituents in the cabin atmosphere. The system also incorporates a state-of-the-art smoke detector designed for microgravity environments. The AMS can be fully integrated with other ECLSS functions or modularized to function independently or replace an existing technology.

Paragon Urine Processor (PUP)

The Paragon Urine Processor (PUP) is an internal R&D effort to characterize the long term performance envelope for IWP-based bladders used in BPA. This single, compact system is being developed to replace the function of two systems on the ISS, the Urine Processing Assembly (UPA) and the Brine Processor Assembly (BPA), thereby reducing volume, mass, and power required to recover water.

Primary Water Processor (PWP)

Paragon’s Primary Water Processor (PWP) ground test unit is a system that receives non-potable, or unclean water, that is then filtered and conditioned to produce potable water, free of biological contaminants, that can be used for crew consumption and in a downstream system to generate oxygen in a closed-loop ECLSS architecture.

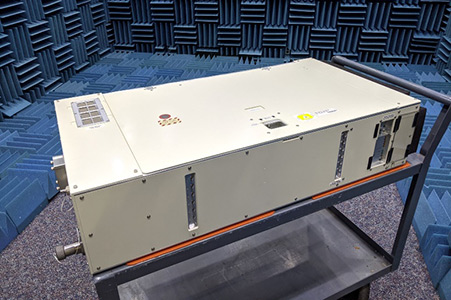

Integrated Support Systems & Electronics

Paragon designs and delivers integrated life support systems and electronics. As spacecraft systems and CONOPS are becoming more sophisticated, modern ECLSS implementations need to stay in lockstep. Paragon has assembled an in-house ECLSS/TCS electronics team which allows rapid development of complete turnkey solutions. This enables us to deliver electronics that work well more quickly and less expensively as well as provide exceptional agility to meet changing customer requirements.

Related programs include StratEx and the ISS Brine Processor Assembly:

Paragon was the prime systems integrator on the StratEx™ mission for manned exploration of the stratosphere above 135,000 feet (41.4 km). Paragon designed and manufactured the ECLSS and thermal control system for the pressure suit and led mission operations (launch, tracking, landing, recovery, and support). The StratEx™ spacesuit shown is a true integrated life support system that demonstrated durability over multiple stratospheric missions and numerous hard parachute landings.

Paragon also designed and delivered the controller for Brine Processor Assembly currently on the ISS. The controller interfaces with the ISS systems and gives real-time data to engineers on the ground.