Paragon has extensive laboratory and testing capabilities which can accommodate component, subsystem, and system level testing in a safe and cost-effective manner, and in a controlled environment. We design, plan, integrate, and execute complex test campaigns to provide better engineering solutions and products to our customers and achieve program goals in terms of cost, schedule and product functionality.

Testing

Radiator and Heat Exchanger Testing

Paragon offers component level and system level performance, leak, and pressure testing for a wide array of thermal management systems. Full-scale radiators can be tested for thermal performance, operating pressures, leak detection, and fluid flow characterization in a controlled and semi-automated test bed.

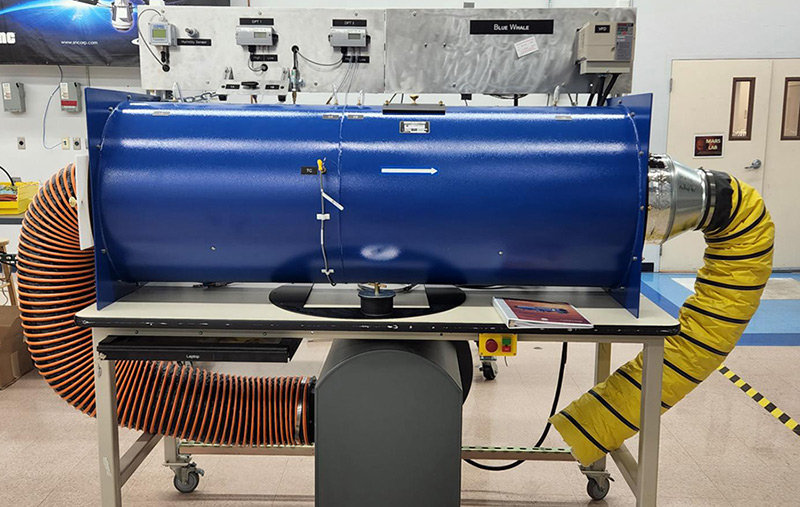

Air Flow, Pressure, & Leak Testing

Paragon’s Air Flow Bench is utilized to verify internal aerodynamic qualities and flow capabilities for ducts, valves, and other components and subsystems that incorporate and/or induce gaseous flows. Blower and fan performance data is also readily captured to verify and validate performance.

Paragon performs burst, proof, and leak pressure testing up to 1500 psig with our pressure test stands. Vacuum leak testing down to 10 Pa (0.075 Torr) can also be accommodated. Pressure decay and helium mass spectrometer leak detection methods are available.

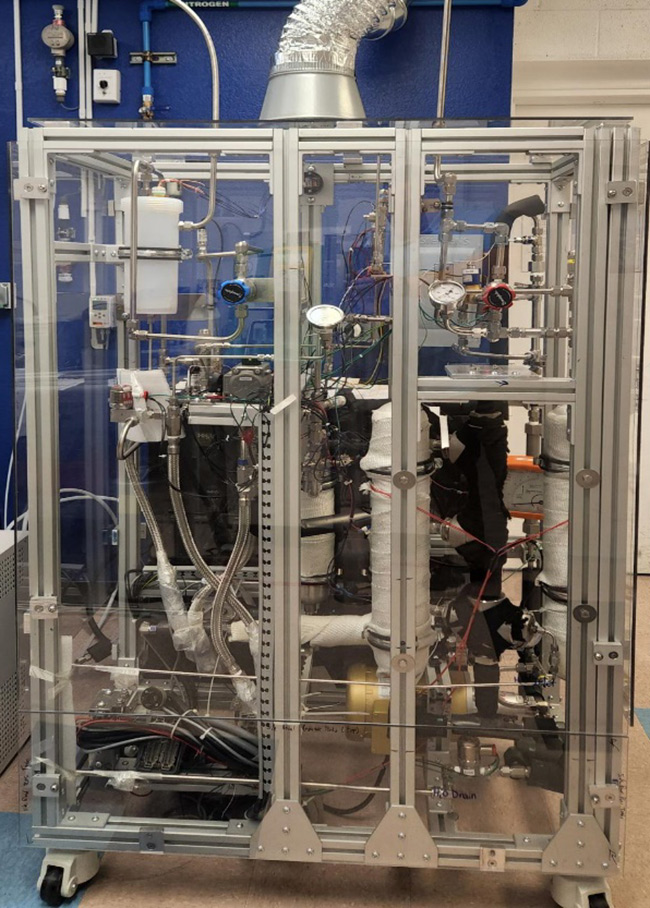

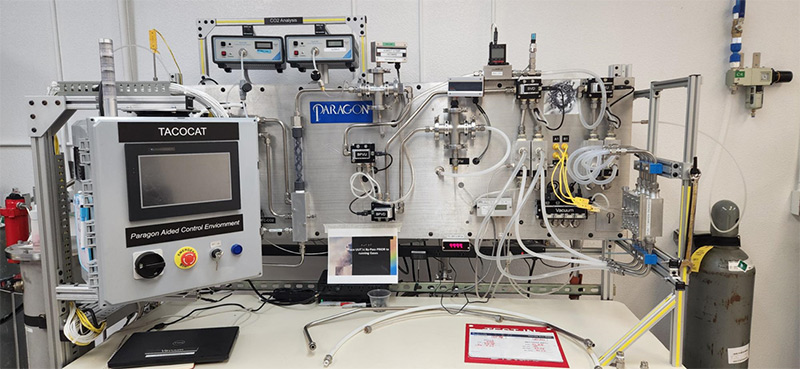

Custom Test Stand Design and Integration

Paragon specializes in designing, integrating, and operating custom test stands to facilitate ECLS and thermal control test campaigns. These stands can be semi or fully automated including safety interlocks for unattended and long duration testing. Data acquisition is handled by either PLC or LabVIEW depending on the needs of the program.

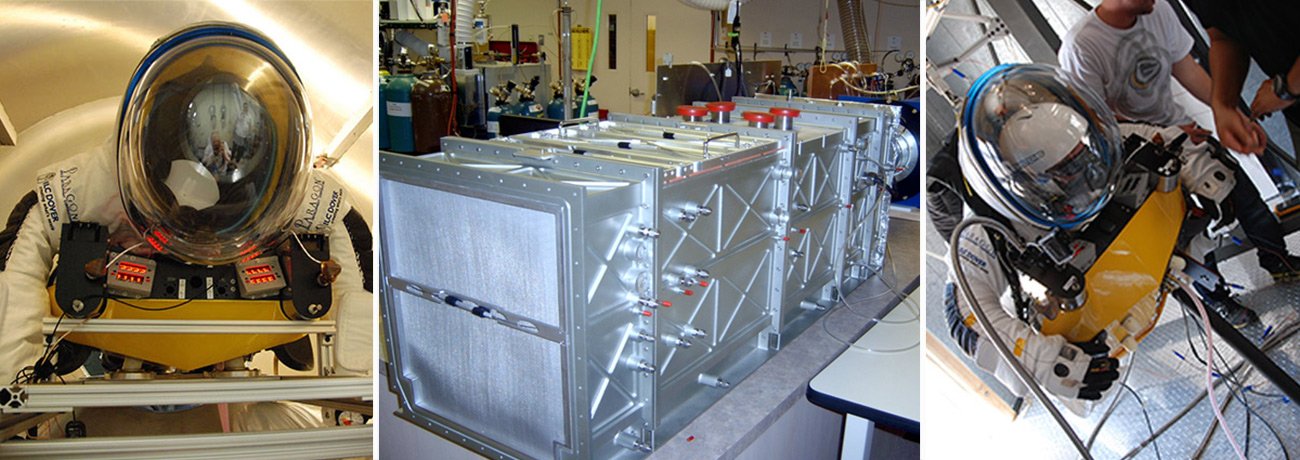

Integrated Testing

In addition to component and subsystem level tests, Paragon also provides expertise in the testing of integrated systems and systems of systems.